Materials science continues to evolve at a rapid pace, introducing innovative solutions that reshape how we approach manufacturing, healthcare, and everyday products. Among these groundbreaking developments, sodiceram stands out as a versatile material with remarkable properties that make it invaluable across multiple industries.

This comprehensive guide explores everything you need to know about sodiceram, from its origins and composition to its diverse applications and future potential. Whether you’re a materials engineer, procurement specialist, or simply curious about advanced materials, this article will provide you with the insights needed to understand why sodiceram is becoming increasingly important in modern applications.

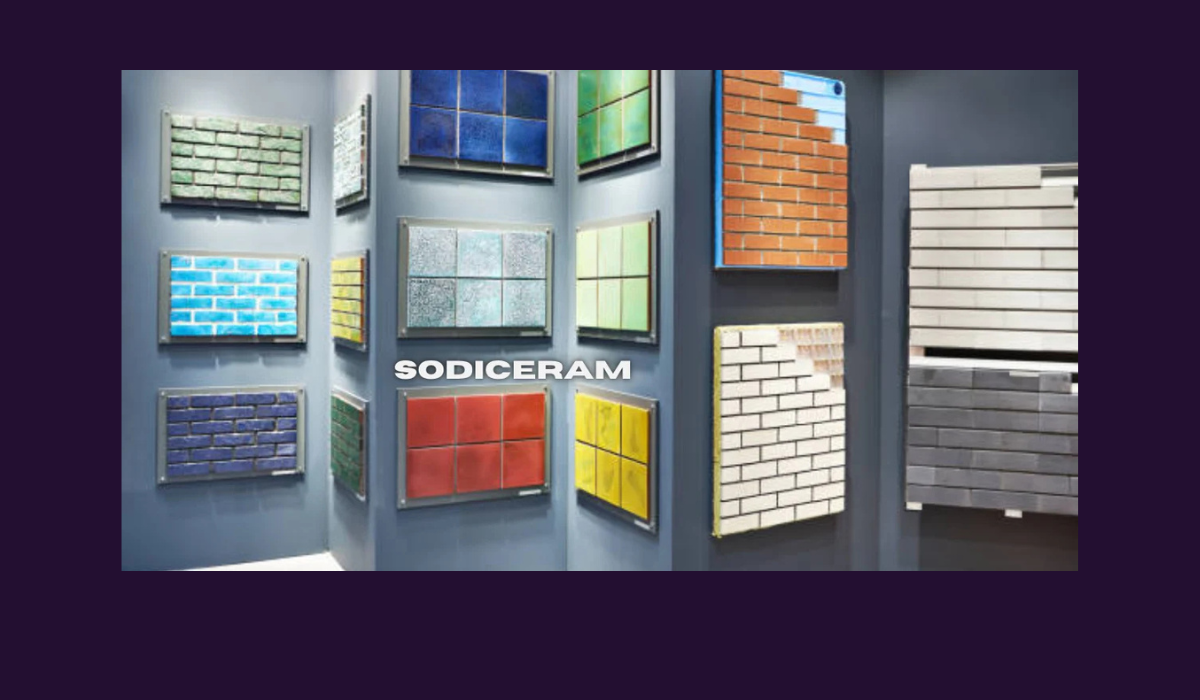

What is Sodiceram?

Sodiceram represents a specialized category of ceramic materials that combines exceptional durability with unique chemical properties. Unlike traditional ceramics, sodiceram exhibits enhanced resistance to thermal shock, chemical corrosion, and mechanical stress, making it suitable for demanding applications where conventional materials fall short.

The material’s name derives from its sodium-based composition, which contributes to its distinctive characteristics. This foundation allows sodiceram to maintain structural integrity under extreme conditions while offering superior performance compared to standard ceramic alternatives.

History and Origin of Sodiceram

Early Development

The development of sodiceram began in specialized research laboratories focused on advancing ceramic technology. Scientists recognized the need for materials that could withstand harsh industrial environments while maintaining consistent performance over extended periods.

Initial research concentrated on modifying traditional ceramic formulations to incorporate sodium compounds in ways that would enhance rather than compromise the material’s properties. This approach required extensive experimentation with different ratios and processing techniques.

Modern Manufacturing

Today’s sodiceram production involves sophisticated manufacturing processes that ensure consistent quality and performance. Advanced kiln technologies and precise temperature control systems enable manufacturers to produce sodiceram with predictable characteristics and minimal variation between batches.

The evolution from laboratory curiosity to commercial reality demonstrates the material’s proven value across diverse applications. Continuous improvements in manufacturing techniques have made sodiceram more accessible while maintaining its exceptional performance standards.

Composition and Properties of Sodiceram

Chemical Structure

Sodiceram’s unique properties stem from its carefully balanced chemical composition. The material typically contains a precise blend of sodium compounds, silicates, and other ceramic materials that work together to create its distinctive characteristics.

The sodium content provides flexibility and thermal stability, while the ceramic matrix offers structural strength and chemical resistance. This combination results in a material that performs exceptionally well under conditions that would damage conventional ceramics.

Key Properties

Thermal Resistance: Sodiceram maintains its structural integrity across wide temperature ranges, making it suitable for applications involving extreme heat or rapid temperature changes.

Chemical Inertness: The material resists degradation when exposed to aggressive chemicals, acids, and bases that would corrode other materials.

Mechanical Strength: Despite its ceramic nature, sodiceram exhibits impressive resistance to impact and mechanical stress.

Electrical Properties: Depending on the specific formulation, sodiceram can provide excellent electrical insulation or controlled conductivity.

Applications of Sodiceram

Industrial Uses

Manufacturing industries have embraced sodiceram for applications requiring exceptional durability and performance. The material’s resistance to wear and chemical attack makes it ideal for components that must function reliably in harsh environments.

Processing Equipment: Sodiceram components in chemical processing plants resist corrosion while maintaining dimensional stability over years of operation.

High-Temperature Applications: Furnace linings and heat exchangers benefit from sodiceram’s ability to withstand extreme temperatures without degradation.

Precision Components: The material’s stability makes it suitable for manufacturing precision parts that must maintain tight tolerances over extended periods.

Medical Applications

The biocompatibility and chemical inertness of sodiceram have opened opportunities in medical device manufacturing. Healthcare applications benefit from the material’s ability to maintain performance while meeting strict safety requirements.

Medical implants and surgical instruments made from sodiceram offer longevity and reliability that patients and healthcare providers demand. The material’s resistance to biological fluids and cleaning agents ensures consistent performance throughout the device’s service life.

Everyday Products

Consumer products increasingly incorporate sodiceram components where durability and reliability are essential. From kitchen appliances to electronic devices, the material’s versatility makes it valuable for applications requiring long-term performance.

Cookware manufacturers utilize sodiceram coatings to create surfaces that resist scratching and maintain their appearance over years of use. Electronics manufacturers appreciate the material’s electrical properties and thermal stability for sensitive components.

Benefits of Using Sodiceram

Durability and Longevity

The exceptional durability of sodiceram translates to longer service life for products and components. This extended lifespan reduces replacement frequency and maintenance requirements, providing significant value over time.

Components made from sodiceram often outlast alternatives by significant margins, maintaining their performance characteristics even under demanding conditions. This reliability makes sodiceram particularly valuable for critical applications where failure is not acceptable.

Cost-Effectiveness

While sodiceram may have higher initial costs compared to conventional materials, its longevity and performance characteristics often result in lower total cost of ownership. Reduced maintenance, fewer replacements, and improved reliability contribute to overall cost savings.

The material’s ability to perform consistently over extended periods eliminates the hidden costs associated with frequent replacements and system downtime. This economic advantage makes sodiceram an attractive option for cost-conscious applications.

Environmental Impact

Sodiceram’s longevity contributes to environmental sustainability by reducing the frequency of replacements and associated waste. The material’s durability means fewer resources are consumed over the product’s lifetime compared to alternatives requiring frequent replacement.

Manufacturing processes for sodiceram have become increasingly efficient, reducing energy consumption and waste generation. These improvements make sodiceram an environmentally responsible choice for applications requiring high-performance materials.

How to Choose the Right Sodiceram Product

Factors to Consider

Selecting the appropriate sodiceram product requires careful consideration of the specific application requirements. Temperature ranges, chemical exposure, mechanical loads, and environmental conditions all influence the optimal material selection.

Operating Conditions: Understanding the temperature, pressure, and chemical environment helps determine the most suitable sodiceram formulation.

Performance Requirements: Identifying critical performance parameters ensures the selected material meets or exceeds application demands.

Installation Constraints: Physical dimensions, mounting requirements, and assembly considerations affect product selection.

Quality and Certifications

Reputable sodiceram manufacturers maintain strict quality control standards and pursue relevant certifications for their products. Industry certifications provide assurance that the material meets established performance and safety standards.

Quality certifications demonstrate the manufacturer’s commitment to consistent production and reliable performance. These credentials are particularly important for applications in regulated industries such as medical devices or aerospace.

Supplier Recommendations

Choosing a reliable supplier is as important as selecting the right material. Established suppliers offer technical support, consistent product availability, and expertise in matching materials to applications.

Look for suppliers with extensive experience in sodiceram applications and a track record of successful projects. Technical support capabilities can prove invaluable during product selection and implementation phases.

Future Trends in Sodiceram Technology

Innovations and Research

Ongoing research continues to expand the capabilities and applications of sodiceram. Advanced manufacturing techniques are enabling new formulations with enhanced properties and improved performance characteristics.

Nanotechnology integration is opening possibilities for sodiceram with unprecedented properties. These advances may lead to applications that are currently impossible with existing materials.

Potential New Applications

Emerging technologies are creating demand for materials with capabilities that sodiceram may be uniquely positioned to provide. From renewable energy systems to advanced manufacturing processes, new applications continue to emerge.

The aerospace industry shows particular interest in sodiceram’s combination of light weight and exceptional performance. Space applications demand materials that can withstand extreme conditions while maintaining reliability over extended missions.

The Versatility and Value of Sodiceram

Sodiceram represents a significant advancement in materials science, offering a unique combination of properties that make it invaluable across diverse applications. Its exceptional durability, chemical resistance, and thermal stability provide solutions for challenges that conventional materials cannot address.

The material’s versatility extends from industrial manufacturing to medical devices and consumer products, demonstrating its broad applicability and proven value. As manufacturing processes continue to improve and new applications emerge, sodiceram’s importance in modern technology will likely continue to grow.

For organizations considering advanced materials for demanding applications, sodiceram offers a compelling combination of performance, reliability, and long-term value. The investment in understanding and implementing sodiceram solutions can provide competitive advantages and improved outcomes across a wide range of applications.

You May Also Like: