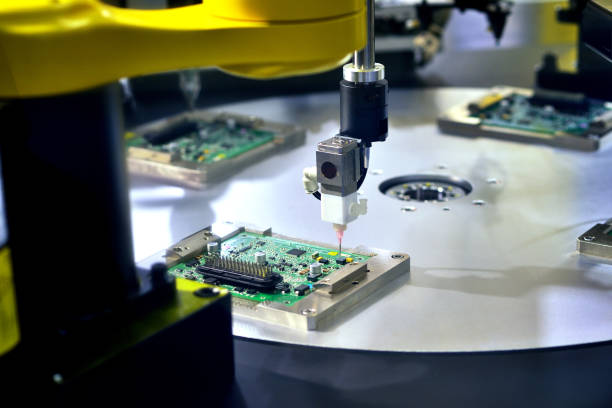

In today’s engineering world, sensors act like the eyes and ears of equipment, gathering data that keeps automation, safety, and productivity on track. You will find these tiny detectors in factory robots, cars, medical gear, and even space probes. Yet few people notice the small metal pieces that keep those sensors working day after day. The truth is, precision turned parts quietly carry most of the workload.

These tiny pieces are made with such exact detail that each one fits the next, no matter what the machine or environment throws at them. The craft behind them blends high-tech machining , strict quality checks, and skilled hands, all aimed at cutting scrap and boosting repeatability. For B2B buyers and engineers, knowing how much they matter can speed up product launches, lower warranty costs, and put a company ahead of the pack.

Keeping Sensor Assemblies Accurate and Consistent

A sensor can deliver crystal-clear readings only if the parts that hold it are built to the same high standard. If a pin is bent, a hole is too big, or a surface is rough, the readings can drift, spike, or stop altogether. That is why teams rely on precision turned components to give every assembly the tight tolerance it needs.

Sensor parts are made to super-tight tolerances, sometimes measured in microns. That level of care guarantees every piece lines up and snaps together exactly as it should. Whether you look at a housing, a connector sleeve, a mount, or a threaded insert, each tiny part locks the sensor in place and stops any wobble or shake that could mess up readings.

The key jobs these precision pieces handle in a sensor assembly include:

- Alignment: Keeping optical or magnetic parts aimed exactly where they belong

- Isolation: Physically blocking shocks or vibrations from reaching sensitive elements

- Connection: Housing electrical contacts or ports with a fit that never fails

- Protection: Acting as shields against dust, moisture, chemicals, and other hazards

Without the high standards of modern precision machining and fabrication, turning out that same level of quality across huge batches would be nearly impossible.

Material Compatibility with Sensor Operating Environments

Today sensors work in some pretty extreme spots-underwater, in space, inside jet engines, and even in the human body. So the materials chosen for precision-turned components have to resist corrosion, heat, pressure, and whatever else comes their way while staying stable for years on end.

Common material choices include:

- Stainless steel because it is strong and shrug-off rust.

- Aluminum alloys for low weight and quick heat spread.

- Brass when good electrical flow and easy cutting matter.

- Titanium for its body-friendly nature and high strength per ounce.

Every metal calls for its own machining and fabrication playbook. Titanium, for example, likes slow cuts and custom tools; aluminum moves fast but needs a clean-up pass, or oxidation and wear settle in. So picking a metal and method shapes sensor speed and the bill at the end.

In critical fields like aerospace pressure sensing or car exhaust sensors, each choice can tip product safety or push it past strict tests.

Enabling Miniaturization and Integration in Micro-Sensors

Miniaturization is now the driving theme in sensor design. As gadgets shrink, stay light, and sip power, the supporting parts must also shrink and smarten up. You see this most clearly in wearables, medical implants, and pocket electronics.

Micro-scale precision turned components cover a wide range of tiny parts, such as:

- Micro connectors and pin housings

- Ultra-small threaded fasteners

- Miniature enclosures with thin walls

- High-density interface modules

Even though these items are often tinier than a grain of rice, each one needs to be sliced, polished, and finished to a mirror-like standard. Makers rely on advanced CNC turning centers, Swiss-style lathes, and robot-controlled measuring gear. Final checks use tools like laser micrometers or scanning electron microscopes to catch any flaw early.

Precision machining and fabrication keep all this work possible by delivering:

- Sub-micron precision and repeatability

- Complex geometries in a single setup

- In-line quality control systems for high-volume consistency

- Fine threading, knurling, and surface finishing techniques

Thanks to these strengths, today’s micro-sensors are tough, space-efficient, and ready to plug into many different systems.

Enhancing Environmental and Electrical Stability

Modern sensors often face wild conditions: sudden heat or cold, dripping water, vibration, and strong electromagnetic fields. Here, precision turned components do more than hold parts together; they guard the inner electronics and keep the data flowing clean.

Some of the ways these features boost sensor toughness include:

- EMI Shielding: Snug shells or wraps that block unwanted radio noise

- Vibration Damping: Grooves, rubber isolators, or foam pads that soak up shakes

- Thermal Conductivity: Light metals like aluminum that pull heat away from circuits

- Sealing: Cut threads, o-rings, and solid flanges that lock out water and dust

Top-notch machining is the only way to put these tiny details in place. Techniques such as ultrasonic cleaning, plasma deburring, and careful anodizing make sure every part looks good and resists corrosion.

In oil rigs or hospital wards, these small steps often spell the difference between normal operation and costly downtime.

Streamlining B2B Supply Chains and Compliance

For product designers, buyers, and quality leads, great parts still have to come fast, in bulk, and with full trace logs. Sensor projects usually run on custom specs, urgent deadlines, and strict regulations.

Good precision turned parts shops give you:

- Rapid Prototyping: Fast, made-to-order pieces straight from CAD files thanks to hooked-up CNC cutters.

- Design for Manufacturability (DFM): Wise engineers tweak your shape so it machines cleanly and costs less.

- Scalability: Go from a handful of test units to full-run output without starting the design over.

- Certification Support: Every batch comes with traceable materials, RoHS papers, and check-up reports.

- Inventory Management: JIT drop-offs and lean Kanban lines keep sensor builders stocked but not overrun.

Sensor brands now count on a short list of machining partners who stay flexible, meet new specs, and never drop quality.

That trust lets them chase bold ideas, knowing the shop down the street will turn a sketch into a metal part-on-time, on-budget, and almost risk-free.

Conclusion: Small Components, Big Impact on Sensor Technology

In today’s data-rich sensor world, strong mechanics matter as much as cutting-edge chips. Precision turned parts are the hidden backbone that keeps devices reliable, scalable, and tough in the field.

In plain words: As sensors shrink yet need better accuracy, precision turned parts and high-end machining will still be the backbone of their reliability and everyday success.

For B2B firms that design, build, or plug in sensors, boosting in-house machining or teaming with top-tier shops is now a smart, not optional, move. When you match quality parts with precision know-how, your company won’t just meet current demands; you’ll steer tomorrow’s breakthroughs.